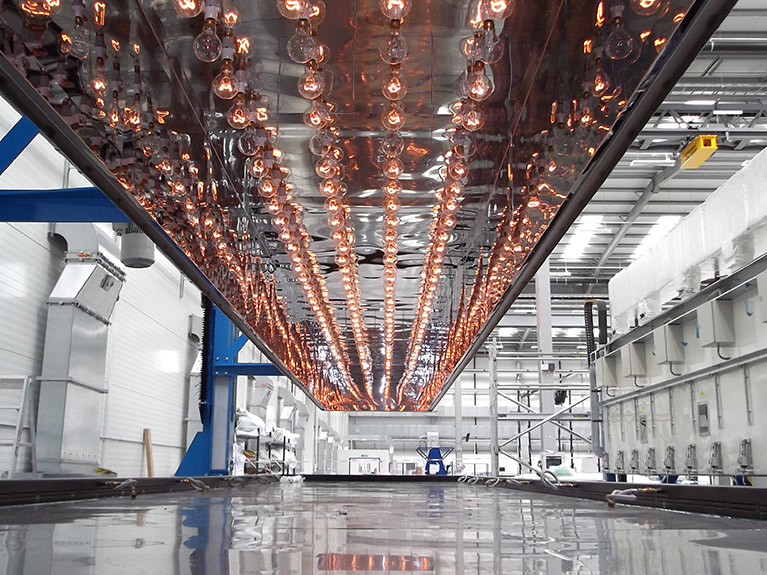

Autoclaves

Autoclaves are pressure vessels operating at high temperature. They are often used to cure components, such as composites, and are used in manufacturing in the aerospace industry.

Our autoclaves are designed to operate at temperatures of up to 400oC, where the normal maximum is 250, and pressures of up to 7 Bar, and reach these in as little as 95 minutes. We have improved thermal efficiency by 25% and achieved temperature uniformity of +/- 0.1 degrees over 50 measuring points within the autoclave. These fix the issue found in many machines that suffer severe thermal stress and accompanying underperformance.

Each AeroThermal autoclave is unique and is built bespoke to our customers’ requirements. We provide the full system and guarantee temperature homogeneity throughout the entire vessel, thanks to our heating and cooling systems.